Cicoil Case Study

The SPACE Cable that Saved Space

Maximum Space Efficiency for Your Tiniest Satellites

Background

Customer manufactures CubeSats, a class of spacecraft called nanosatellites. CubeSats measure about four inches on each side and weigh less than three pounds, with a volume of about one quart. The CubeSats will be launched for spaceflight; the International Space Station will be used to deploy them as well. Mission Critical assemblies are a Must.

Challenge

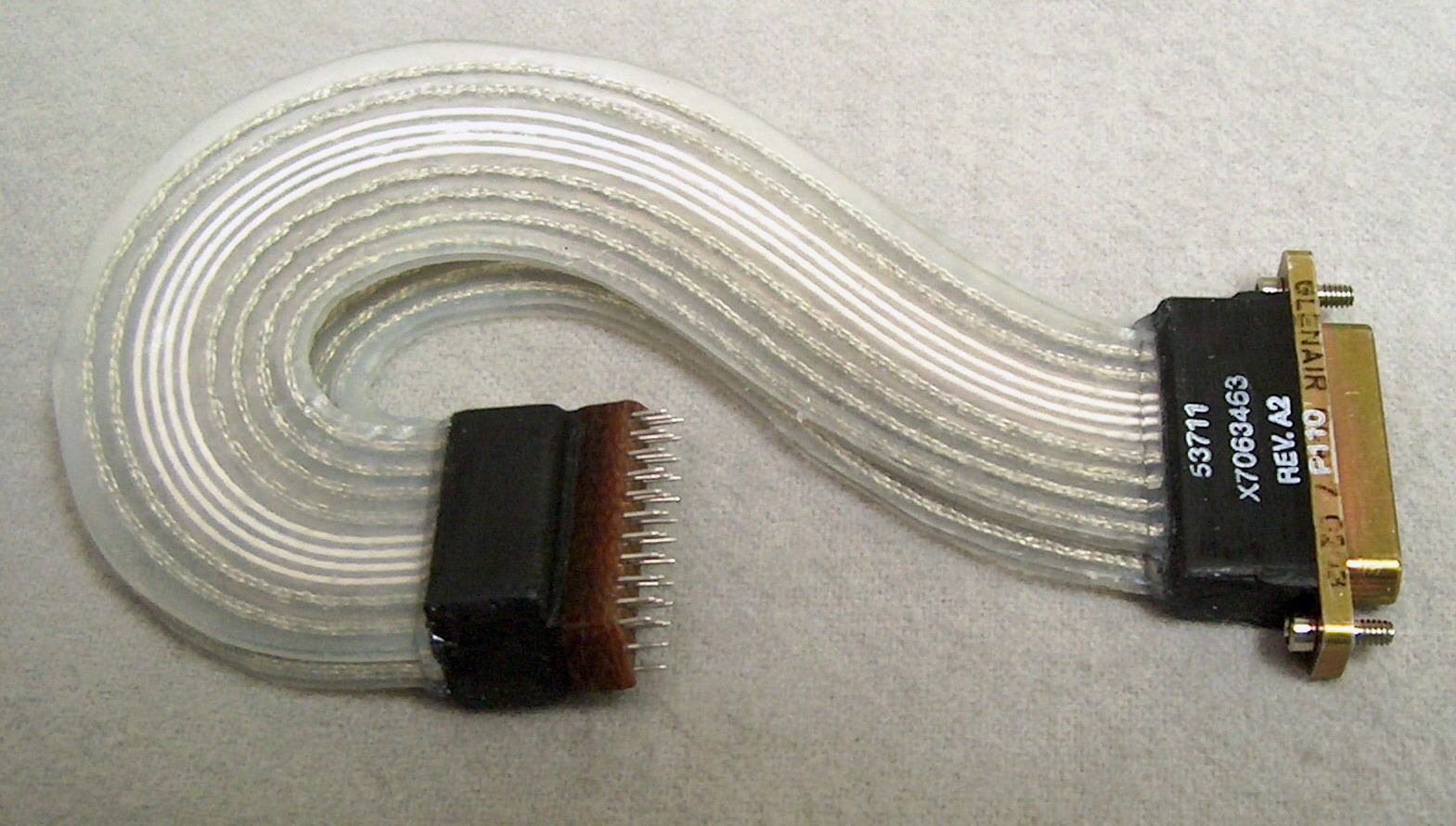

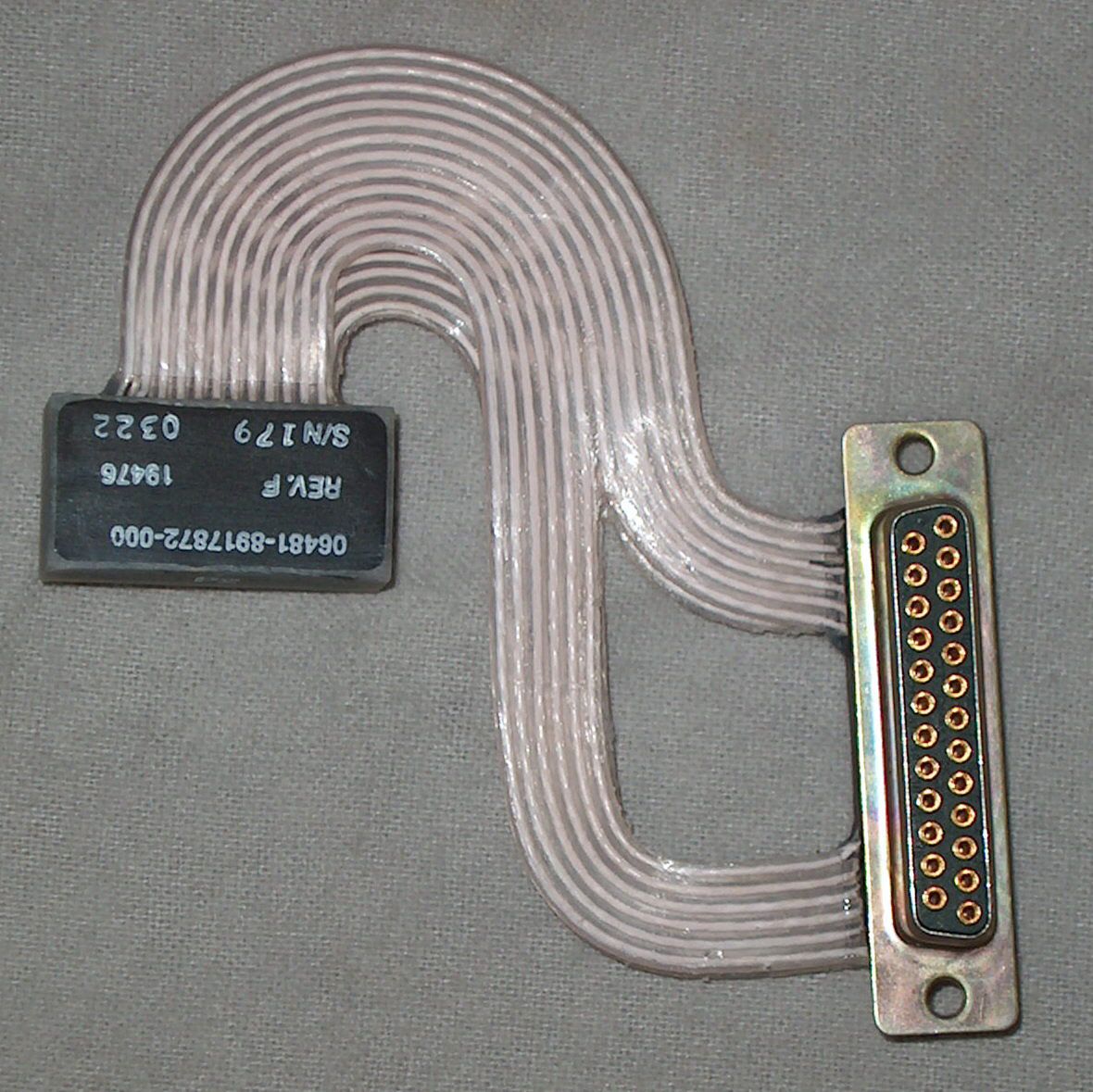

Customer required a fully terminated Camera Link assembly that would provide exceptional performance and EMI protection. A cable that would consume minimal precious space, and also minimize weight. The cable also had to have the capability to survive exposure to the harsh environments of Space. The customer found no conventional cabling that provided a compatible solution for their system.

Solution

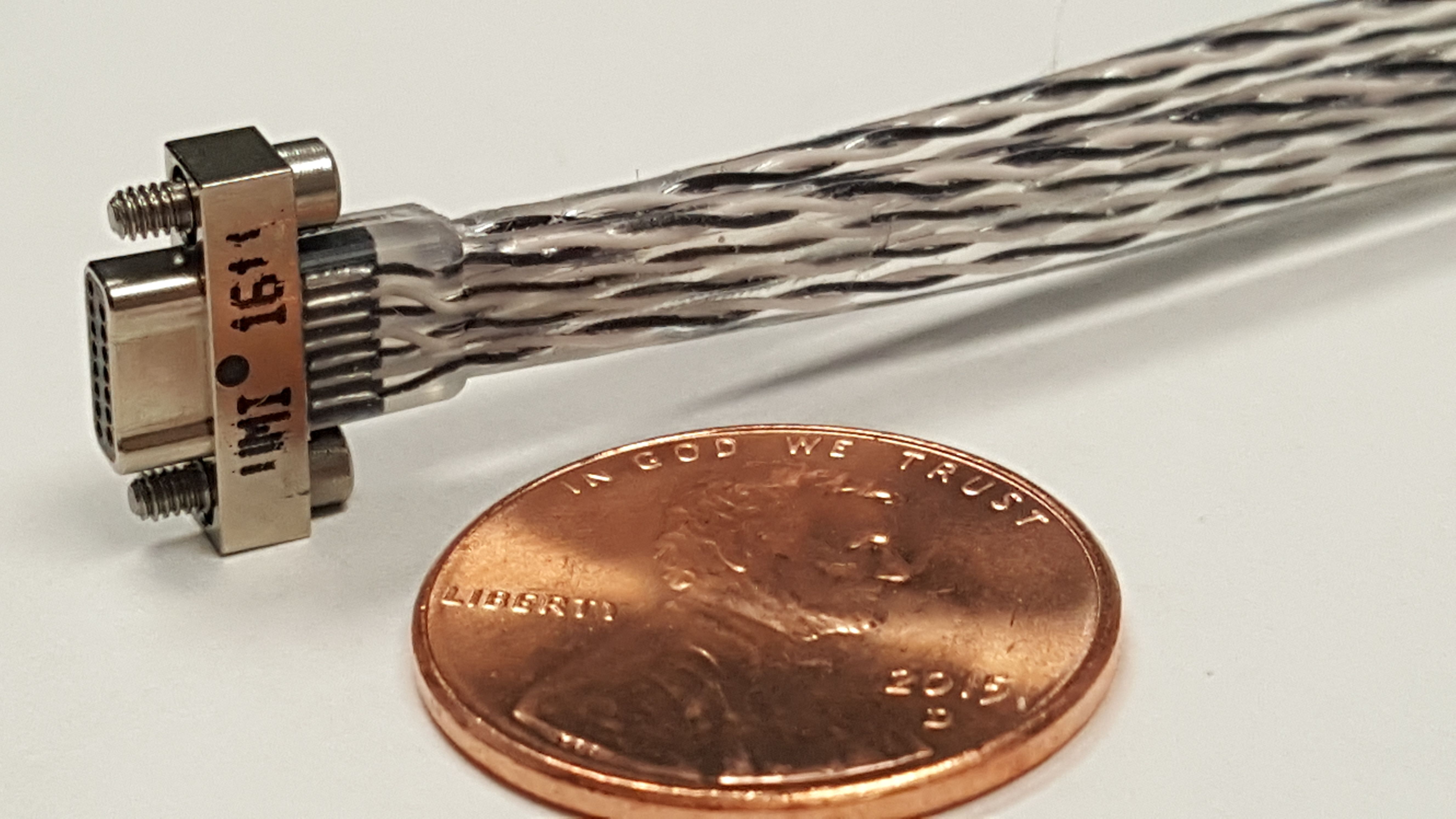

Cicoil’s winning solution is a highly flexible, flat Camera Link Cable assembly. Its dual shielded design is comprised of an inner foil shield that provides 100% coverage, and an overall tinned copper braid with 90% coverage. A durable, yet flexible PFA insulation is layered between each shield, which protects the inner foil shield from making contact with the outer tinned copper braid. The flat design requires less space than round cable, ultra-fine conductor strands reduce weight while providing unsurpassed electrical/signal attributes. Parallel conductors and Flexx-Sil™ Jacket provide for mechanical strength, superior flexibility with durability under continuous motion.

Benefits of Cicoil Flat Cable

- With Flexx-Sil™ jacketing, cables are ultra-flexible and withstand the shock, vibration, and other rigors of supersonic flight

- Allow for extremely compact, lightweight cable designs for weight- & space-sensitive designs

- Low Outgassing materials are Space Flight approved by NASA

- Resistant to radiation, UV light, ozone, corona discharge, sunlight, and extreme temperatures (-65°C to +260°C)

Results

In addition to the Camera Link Cables, Cicoil provided fully terminated assemblies—certified IPC 620 Space Addendum. The cables met all of the customer’s test requirements: outgas, bend radius, flex cycles, Camera Link protocol, electrical and signal.

Per the customer:

Per the customer:

“As we were very space and weight constrained on board the satellite, conventional cabling solutions were not compatible with our application. We required a custom cable assembly that would survive and perform in space sensitive environment in a Space Orbit application."

Another Mission Critical solution provided by Cicoil.

Speak with one of our Flexible Cable Solutions Specialists to discuss your inflexible application requirements. Our team of experts will help with all of your cabling, assembly and value-added needs.

A Few Related Customers