Non-LSZH Cables

vs

Cicoil LSZH Cables

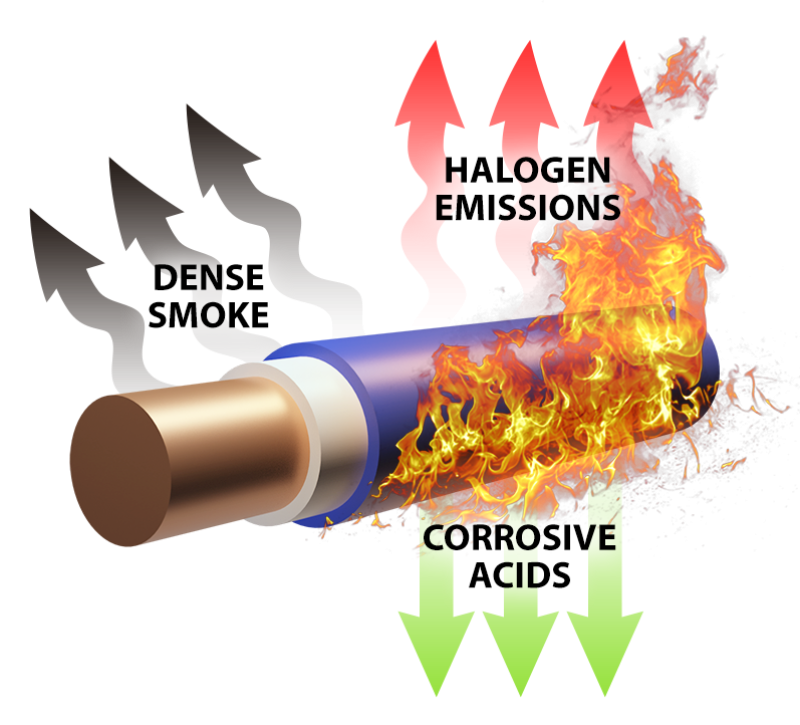

Non-LSZH Cables

vs

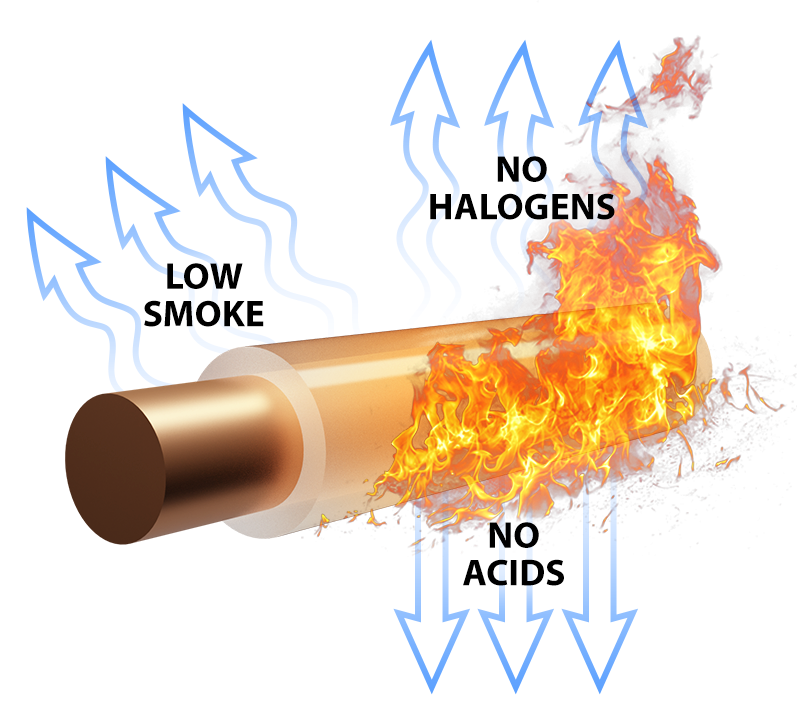

Cicoil LSZH Cables

Common jacketing materials like PVC, Neoprene, and PTFE/Teflon™ require the addition of halogens to reduce flammability. In cases, however, where combustion does occur, burning halogens result in dense smoke and corrosive/toxic gases.

vs

Cicoil’s Flexx-Sil™ cable jacketing is inherently flame resistant and uses NO HALOGENS. Flexx-Sil™ is our proprietary elastomeric cable encapsulation material that is naturally resistant to combustion, and if ignited under extreme conditions, does not produce black smoke or toxic gas or corrosive substances.

Cables containing halogens present a serious risk to any populated environment. If exposed to water after being burned—as in the case of the use of fire suppression systems or even humidity in the air—halogen-containing cable/wire jacketing will release dangerous or even deadly chemicals such as hydrochloric acid.

vs

A safer choice for all environments, but essential when the safety of human life is a top priority, as in highly populated facilities, mass transit, and crewed vehicles. In the event of a fire, the danger to individuals will not be compounded by toxic, halogen-based airborne chemicals.

The microcircuitry aboard most electronic equipment is particularly susceptible to the acidic moisture produced by materials without LSZH classification.

vs

Mitigates damage done to equipment during a fire. Flexx-Sil™ does not release the corrosive chemicals that eat away at delicate electronics and computer systems.

Flame and combustion retardation additives used on common cable and wire jacketing typically stiffens the material, making the product less flexible and compliant, and susceptible to a shorter functional life in motion applications.

vs

Even with LSZH classification, Flexx-Sil™ jacketing provides extreme flexibility, is 100% transparent, self-heals small punctures, and remains very durable within stressful environmental conditions.

Industry standard cables are infused with color additives that contain contaminants and don't allow for inspection of the cable for possible wire shorts and safety issues.

vs

Crystal-clear jacketed cables offer 100% transparency, which allows for quick, safe inspection of cables in just about any application.

LSZH Cables from Other Manufacturers

vs

Cicoil LSZH Cables

Typically, LSZH cables require filler materials to make them low smoke and zero halogen. This makes the jacket less resistant to chemicals, water, and other environmental stresses as compared to non-LSZH cables, and may even inhibit the cables' mechanical and electrical characteristics.

vs

Cicoil’s Flexx-Sil™ jacketing material is flame retardant by nature, completely non-toxic, and requires no additives to achieve zero halogen. It also offers excellent resistance to harsh environments, water, acid and many chemicals.

The materials used to make the cable LSZH limits the flexibility of the cable and impedes its performance in continuous motion and robotics applications.

vs

Cicoil’s flat cables are designed to prevent wire breakage, jacket punctures, and operational failure when exposed to tight bending, flexing, mechanical stress, and harsh environments.

The outer jacket of LSZH cables may crack during installation or tight bends, so lubricants are recommended to prevent jacket damage.

vs

Cicoil’s unique cable jacket requires minimal maintenance thanks to its self-healing properties and integrity through long term exposure to tight bending, confined spaces, and even vibration.