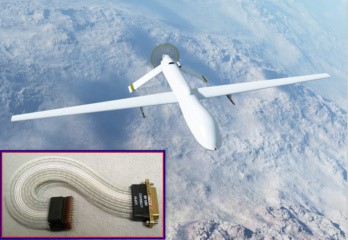

Flat Cables for Unmanned Systems

Valencia, CA; May 5, 2017: For unmanned systems, intelligent robotics and drone applications that require lightweight and flexible cable designs, Cicoil offers kink resistant, rugged and space saving flat cables and assemblies. In addition, the highly durable flat cables are designed to provide absolute reliability in Mission Critical applications.

Each Cicoil cable can incorporate a variety of elements, including power conductors, shielded signal pairs, video and coax conductors, and other design elements like Cicoil's patented StripMount™ fastening strip, all in a single compact cable design. Cables are available in continuous lengths, cut to order, or as assemblies, complete with connectors of your choice, 100% tested and inspected.

Cicoil's patented computer-controlled extrusion process allows each individual component to be placed in a flat parallel profile, precisely controlling the spacing of each component, insulation thickness and the overall cable shape. This ensures that each of the internal pairs or conductors do not rub against each other, wear during operation and provide optimum EMI/RFI suppression. The rectangular cross-section also allows multiple flat cables to stack, or layer, with almost no wasted dead space between cables, providing maximum conductor density for a given volume.

The unique outer jacket is self-healing from small punctures and will not wear, crack or deform due to long term exposure to vibration, sunlight, temperature extremes (-65°C to +165°C), acid, submersion in water, sea ice, steam, coarse sand, flames, radiation, mechanical stress, humidity, ozone, UV light, fungus, high altitudes and many chemicals

Cicoil's UL Recognized, RoHS Compliant & CE Conforming cables are manufactured in an automated, climate controlled environment, and exceed the NASA 1124 outgassing specifications for space use and vacuum requirements. In addition, Cicoil offers anti-friction coating options and custom shaped cable designs by request.

If you would like to learn how Cicoil developed the First IDC Ribbon Cable, helped put a Man on the Moon, and find out more about our Innovative Flat Cable Technology, please contact our office at 661-295-1295 to discuss your application or to set up an on-site visit to your location.

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for more than sixty years. The company's Patented Flexx-Sil™ Flat Cable Technology provides high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's flat cables are used in thousands of demanding applications; including aircraft fuel control cells, semiconductor automation, and the Space Shuttle. Cicoil designs and manufactures its Flexx-Sil™ jacketed cables and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard. Visit www.cicoil.com for more information, or call 661-295-1295 to speak to an application engineer.

Each Cicoil cable can incorporate a variety of elements, including power conductors, shielded signal pairs, video and coax conductors, and other design elements like Cicoil's patented StripMount™ fastening strip, all in a single compact cable design. Cables are available in continuous lengths, cut to order, or as assemblies, complete with connectors of your choice, 100% tested and inspected.

Cicoil's patented computer-controlled extrusion process allows each individual component to be placed in a flat parallel profile, precisely controlling the spacing of each component, insulation thickness and the overall cable shape. This ensures that each of the internal pairs or conductors do not rub against each other, wear during operation and provide optimum EMI/RFI suppression. The rectangular cross-section also allows multiple flat cables to stack, or layer, with almost no wasted dead space between cables, providing maximum conductor density for a given volume.

The unique outer jacket is self-healing from small punctures and will not wear, crack or deform due to long term exposure to vibration, sunlight, temperature extremes (-65°C to +165°C), acid, submersion in water, sea ice, steam, coarse sand, flames, radiation, mechanical stress, humidity, ozone, UV light, fungus, high altitudes and many chemicals

Cicoil's UL Recognized, RoHS Compliant & CE Conforming cables are manufactured in an automated, climate controlled environment, and exceed the NASA 1124 outgassing specifications for space use and vacuum requirements. In addition, Cicoil offers anti-friction coating options and custom shaped cable designs by request.

If you would like to learn how Cicoil developed the First IDC Ribbon Cable, helped put a Man on the Moon, and find out more about our Innovative Flat Cable Technology, please contact our office at 661-295-1295 to discuss your application or to set up an on-site visit to your location.

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for more than sixty years. The company's Patented Flexx-Sil™ Flat Cable Technology provides high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's flat cables are used in thousands of demanding applications; including aircraft fuel control cells, semiconductor automation, and the Space Shuttle. Cicoil designs and manufactures its Flexx-Sil™ jacketed cables and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard. Visit www.cicoil.com for more information, or call 661-295-1295 to speak to an application engineer.