Talc-Free Flat Cables

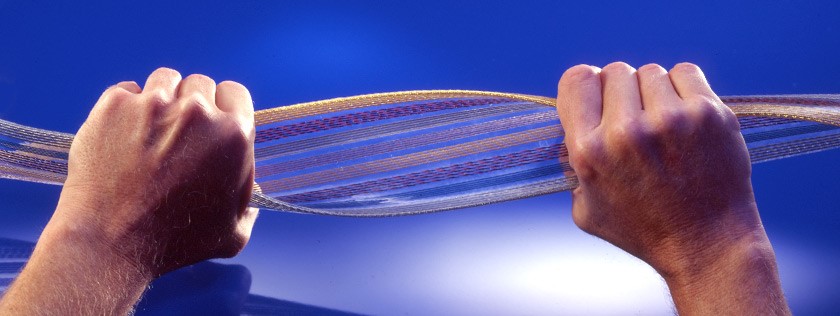

Valencia, CA; July 17, 2017: For motion applications that require flexible and lightweight cable designs, Cicoil offers highly flexible flat cables, which eliminates the need for fillers, tape and potentially harmful and contaminating internal lubricants, such as talc, that are necessary in flexible round PVC cables.

Cicoil's patented extrusion process allows individual conductors, pairs and even tubing to be placed in a small, flat profile, precisely controlling the spacing of each component, insulation thickness and the overall cable shape. Each component is separately encased in a solid, one-piece construction, ensuring that they do not rub against each other and wear during a lifetime of 15 million flexing cycles. The rectangular cross-section also allows multiple flat cables to stack, or layer, with almost no wasted dead space between cables, providing maximum conductor density for a given volume.

Flat cables also have greater surface-to-volume ratio than talc filled round cables, consequently having higher efficiency in dissipating heat. This allows a higher current level for a given temperature rise and conductor cross-section. Unfortunately for some round cable manufacturers, the elimination of talc in their designs will be exposed to heat build-up, conductors sticking together and ultimately cable failure.

In addition, the Halogen-free outer jacket is self-healing from small punctures and will not wear, crack or deform due to long term exposure to vibration, sunlight, temperature extremes (-65°C to +165°C), acid, submersion in water, sea ice, steam, coarse sand, flames, radiation, alcohol, mechanical stress, humidity, ozone, UV light, high altitudes, autoclave and many chemicals.

Standard "off the shelf" flat cables are available for immediate delivery and cable assemblies, complete with connectors are offered in 3 foot, 6 foot and 12 foot lengths. Cicoil offers low-friction coatings, custom shape and torsion designs by request.

Cicoil's Flat Cables are UL Recognized, CE Conforming, RoHS & REACH Compliant, Class 1 Clean Room Rated, are manufactured in an automated, climate controlled environment.

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for over sixty years. The company's Patented Flexx-Sil™ Flat Cable Technology provides high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's flat cables are used in thousands of demanding applications; including aircraft fuel control cells, semiconductor automation, and the Space Shuttle. Cicoil designs and manufactures its Flexx-Sil™ jacketed cables and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard. Visit www.cicoil.com for more information, or call 661-295-1295 to speak to an application engineer.

Cicoil's patented extrusion process allows individual conductors, pairs and even tubing to be placed in a small, flat profile, precisely controlling the spacing of each component, insulation thickness and the overall cable shape. Each component is separately encased in a solid, one-piece construction, ensuring that they do not rub against each other and wear during a lifetime of 15 million flexing cycles. The rectangular cross-section also allows multiple flat cables to stack, or layer, with almost no wasted dead space between cables, providing maximum conductor density for a given volume.

Flat cables also have greater surface-to-volume ratio than talc filled round cables, consequently having higher efficiency in dissipating heat. This allows a higher current level for a given temperature rise and conductor cross-section. Unfortunately for some round cable manufacturers, the elimination of talc in their designs will be exposed to heat build-up, conductors sticking together and ultimately cable failure.

In addition, the Halogen-free outer jacket is self-healing from small punctures and will not wear, crack or deform due to long term exposure to vibration, sunlight, temperature extremes (-65°C to +165°C), acid, submersion in water, sea ice, steam, coarse sand, flames, radiation, alcohol, mechanical stress, humidity, ozone, UV light, high altitudes, autoclave and many chemicals.

Standard "off the shelf" flat cables are available for immediate delivery and cable assemblies, complete with connectors are offered in 3 foot, 6 foot and 12 foot lengths. Cicoil offers low-friction coatings, custom shape and torsion designs by request.

Cicoil's Flat Cables are UL Recognized, CE Conforming, RoHS & REACH Compliant, Class 1 Clean Room Rated, are manufactured in an automated, climate controlled environment.

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for over sixty years. The company's Patented Flexx-Sil™ Flat Cable Technology provides high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's flat cables are used in thousands of demanding applications; including aircraft fuel control cells, semiconductor automation, and the Space Shuttle. Cicoil designs and manufactures its Flexx-Sil™ jacketed cables and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard. Visit www.cicoil.com for more information, or call 661-295-1295 to speak to an application engineer.