Cicoil Cable vs The Challengers

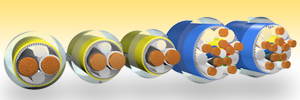

Extruded Flat Cables

When failure is not an option, Cicoil flat cable provides true flexibility and tremendous resilience to shock and vibration. And our flat cables are available in miniature configurations, with wires as small as 44 AWG.

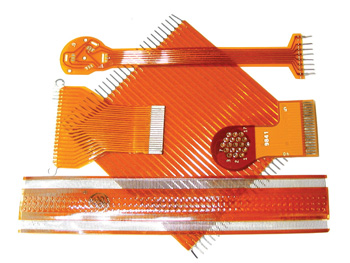

Flex Circuits

Flex circuits have some useful properties; however, many designers try to make use of them beyond the limits of the flex circuit's capability. The reality is that despite the name, flex circuits have limited flexing capability. Over flexing and stress can cause cracks and breaks in the brittle circuit tracing.

Take a look below at the Tale of the Tape. Cicoil Extruded Flexx-Sil™ Flat Cable is The Clear Winner!

Extruded Flat Cables

Flex Circuits

QUALITY

Each wire can have its own shield.

Shielding attained by using adjacent conductors or flat shield planes above and below the circuit trace layer; results in larger and stiffer assemblies.

High strand count, high flexibility and flex life. Can withstand >10 million+ flex cycles.

Have solid, flat conductors and flex life below a million cycles.

STRENGTH & RELIABILITY

CICOIL flat cable is durable and will withstand severe impact and rough handling.

Flex circuits are very ridged and susceptible to micro- cracks and failure in severe vibration applications.

CICOIL flat cable is durable and will withstand severe impact and rough handling.

Flex circuits are more fragile. They can be easily dented, bent and damaged from minor impact or improper handling.

VERSATILITY & COST

Can include twinax, coax, digital communications, power and twisted pair wires. Pneumatics and fiber optics can also be included.

Single conductors only (typical).

Can be formed to custom fit in equipment to aid installation to make installation a quick task.

Can be shaped to fit the installation path. This eases assembly and maximizes real estate use.

Inexpensive custom cable tooling of $250. Tooling is made in-house in less than a day.

Large initial tooling costs. Once made, tooling is expensive to change or new tooling may be required.

Short lead time of 1- 2 weeks using wire from our large inventory.

Long lead times are typical and flex circuits does not lend itself to rapid prototyping.

Cable is produced in continuous lengths (bulk) that can be cut to suit various applications.

Flex circuits are individually made and the size is fixed according to the tooling.

Flat cable can be installed in tight spaces where equivalent round cable won't fit.

Flex circuits can be used in small spaces where equivalent round cable won't fit.